Updating your warehouse can be a challenge, one of the most important things to consider are do you use Structural or Rolled Formed Steel Rack , What is the difference? Structural Vs. Roll-Formed Racking Systems both have various features and durability. Roll Formed components are lighter, easily snap together and as a result are less expensive to buy and install. However they are limited to the amount of weight that the can support are and are more easily damaged from fork lift trucks. Structural components are made from heavier, cast steel and can provide higher load capacities. Since structural components are bolted together, they can take slightly more labor to install. However require less maintenance.

Structural Selective Pallet Rack Advantages:

- Strength: Hot rolled structural channel steel provides quality and strength. Fully bolted connections yield a stronger and more rigid system.

- Durability: high use applications for long lasting performance such as heavy loads, quick turnover and harsh conditions. Ideal for freezers, coolers and distribution facilities.

- Versatility: Offers a wide range of designs and load capacities. Common configurations include pushback, flow and drive-in applications.

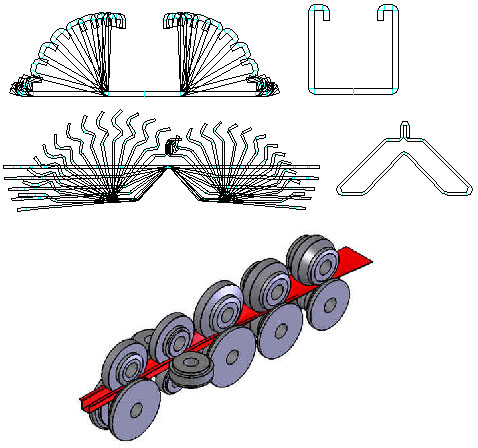

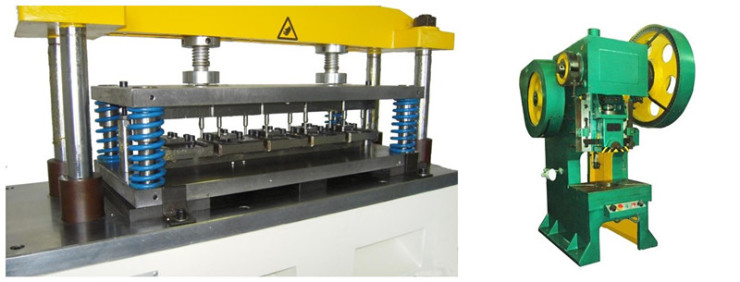

Roll Formed Pallet Rack Advantages:

- Adaptable: Adapts to the weight, volume and size of many products and the teardrop style is interchangeable among different manufacturers. Excellent for warehouses storing products with varying sizes.

- Convenience: A boltless, easy to assemble product. Provides great stock management with direct access to each pallet. Because the clips can be moved quickly, shelves can be easily changed to accommodate various heights and load sizes.

- Cost-Effective: Less expensive and more adaptable than structural steel racks, the cost provides a good return on investment. The roll-formed design, using flat rolled carbon steel, still provides strength necessary for most applications.

Roll Formed Rack Application