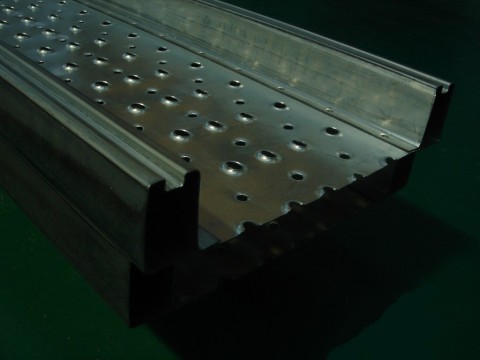

Scaffolding Roll Forming Machine

Introduction

Scaffolding roll forming machine is composed of uncoiler, levelling device, servo feeding device, press machine, main roll forming machine, hydraulic station, control system and output tables.

- Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel 250mpa-620mpa

- Working Speed: 12-15 meters / min

- Forming machine: about 20 stations

- Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

- Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

- Driven system: drive by 160 type gear box

- Main Power with reducer: 11KW WH Chinese Famous

- Cutting: Hydraulic Cutting Cr12mov

- Material of Cutting Knife: Cr12Mov, Quench HRC58-62

- Hydraulic Station Power: 5.5KW Famous Chinese Brand

- The whole machine is controlled by industry computer-PLC

- PLC–Panasonic, Japan E