Description

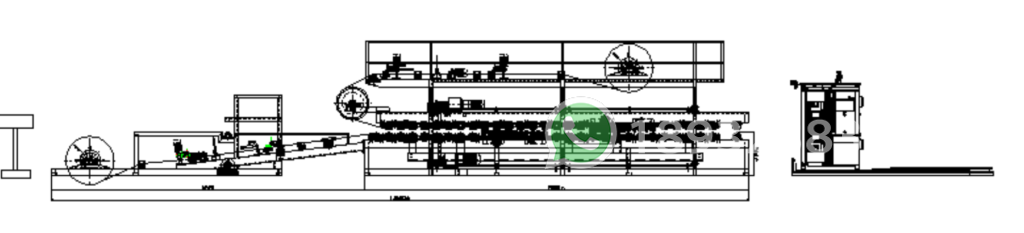

Rock Wool & EPS Sandwich Panel Production Line is designed to produce rock wool panel or EPS sandwich panel, which can be used for clean room and building construction industry. The whole rock wool sandwich panel production line is composed of roof roll forming machine, glue machine, pressing machine, saw cutting machine, outer table, hydraulic system, PLC control system, and auto stack as option. The output of this rock wool sandwich panel production line is 2500m2 every 8 hours working shift. it can produce 2500m2 EPS sandwich panel or rock wool sandwich panel every 8 hours working shift. The whole line require land space 40 meters long x 10 meters wide.

Application

Rock wool sandwich panels/ EPS sandwich panels are a popular choice for clean room building, roofing and cladding purposes due to their exceptional insulation properties and durability. The rock wool sandwich panels consist of a core made from rockwool, also known as mineral wool, which is sandwiched between two layers of metal sheets. The combination of rock wool and metal steel creates a versatile building material that offers excellent thermal and acoustic insulation, fire resistance, and structural strength.

Following more applications of rock wool sandwich panel:

1. Diagnosis, treatment, purification and decoration design industry

The medical industry, due to its unique environment, has very high requirements for indoor cleanliness and decoration. Rock wool clean room sandwich panel make up for the shortcomings of other building decoration materials in this industry. The surface coating of the rock wool clean room panel has many excellent properties, including fire safety, rich colors, corrosion resistance against strong acids and alkali, no dust, easy to clean, etc. At present, the decorative design of rock wool clean room panels in the medical industry has received high praise from the general public.

2. Food and health care production lines

Food factories are subject to very strict regulations in our country. The production and processing of food and health care products have very high requirements for cleanliness. In decoration design, try to ensure food environmental hygiene. The characteristics of rock wool clean room panel ensure the production and manufacturing of food and health care products.

3. Laboratory partitions and suspended ceilings

As a scientific research place, the laboratory has very high requirements for decoration design. In addition to the stable properties of wall decoration materials, it is also required that the materials will not affect biochemical experiments. Ordinary explosion-proof glass building decoration materials will cause static electricity and damage the experimental results.

The clean room panel is made of chemical fiber concrete slabs, which have no radiation and no electrostatic induction, which can effectively eliminate the influencing factors of the biochemistry laboratory. The application of clean room panel in this industry will eventually become more and more widespread.

Rock wool clean room panel is an emerging new environmentally friendly material with many advantages and characteristics. With the development of science and technology and economic development, the purpose of clean room panel will become more and more extensive.

Working Process

Operation Flow:

Roll forming – Gluing – Pressing Machine -Saw Cutting – Auto Stack

We are professional manufacturer of rock wool clean room panel machine for more than 30 years. The advantage of using our Rock Wool & EPS Sandwich Panel Production Line include high efficiency ( that you just need set the product length and quantity on touch screen, then the machine will run automatically), consistent product quality. These characteristics are essential for the building industry.

Technical Specification

| Rock Wool & EPS Sandwich Panel Production Line | ||

| No. | Item | Specification |

| 1 | Suitable material | Galvanized Coil, PPGI, Color Steel |

| Thickness(mm):0.3-0.8 | ||

| Yield strength: 250 – 550MPa | ||

| Tensil stress( Mpa):G350Mpa-G550Mpa | ||

| 2 | Nominal forming speed(m/min) | 0-15 |

| 3 | Total motor power | 22 Kw |

| 4 | Machine weight | 15 Tons |

| 5 | Annual production capacity | 600000m2 |

| 11 | Power supply | 380V 50Hz 3PH |

| 12 | Machine color | Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing Rock Wool & EPS Sandwich Panel Production Line?

A: We have rich experience of producing Rock Wool & EPS Sandwich Panel Production Line, till now more than 1500 sets solar strut channel roll forming machine produced and sold to customers local China and all over the world.

2. Q: What is delivery time of Rock Wool & EPS Sandwich Panel Production Line?

A: 60 days after contract confirmation.

3. Q: What is your machine annual production capacity?

A: The machine annual production capacity is 600000m2.

4. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Rock-Wool-Sandwich-Panel-Production-Line-480x640.jpg)

Rock-Wool-Sandwich-Panel-Production-Line.jpg)