Solar Strut Channel Making Machine

Solar Strut Channel Making Machine

Introduction

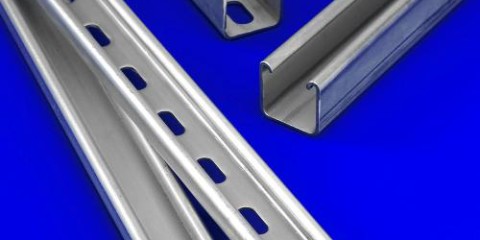

Solar Strut Channel Making Machine can be used to produce strut channels with height from 20mm to 82mm. With gearbox transmission and fly-saw cutting, our strut channel roll forming machines has the advantage of high stability, easy operation and long lifetime.

Our Solar Strut Channel Making Machine is composed of decoiler, punching device, main roll forming, cutting device, hydraulic station, control cabinet, and outer table.

Technical Parameter

| Product name | Strut channel roll forming machine | |||

| NO. | Items | Parameters | Remark | |

| 1 | SuitableMaterial | Type | GI/GL | |

| Width | 1000/1200/1250mm | Custom | ||

| Thickness | 0.70—1.20mm | |||

| 2 | ProductSpecifications | Length | Any length | Programmed |

| Length Tolerance | ±1.5mm/6m | |||

| 3 | Working Speed | 25 m/min | Standard machine | |

| 4 | Control System | Mitsubishi/Siemens/Panasonic PLC& transducer | Custom | |

| 5 | Total Power | About 20KW | ||

| 6 | Total Weight | About 15T | Up to final design | |

Application

Strut channel is used to mount, brace, support, and connect lightweight structural loads in building construction. These include pipes, electrical and data wire, mechanical systems such as ventilation, air conditioning, and other mechanical sysyems. Strut channel is also used for other applications that require a strong framework, such as workbenches, shelving systems, equipment racks,etc. Specially made sockets are available to tighten nuts, bolts, etc, inside the channel, normal sockets are unable to fit through the opening.